SERVICES

Machine and System Debug and Upgrade

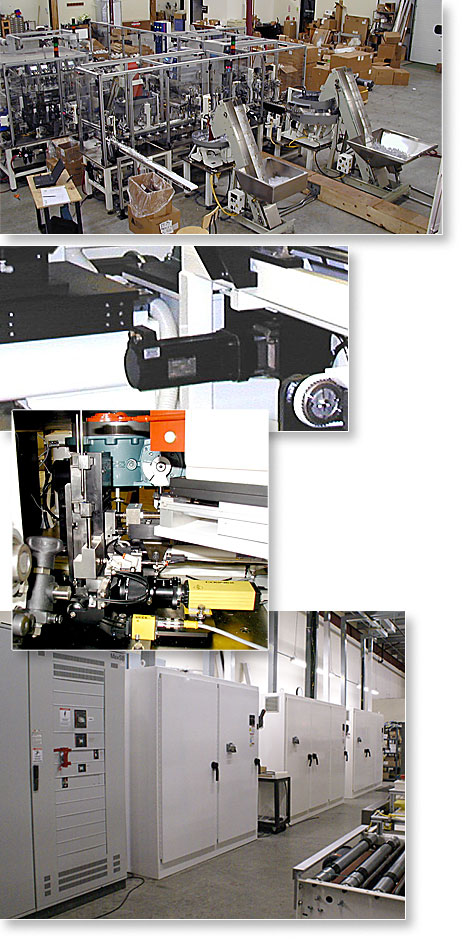

Many manufacturing systems are not meeting production requirements, due to poor equipment performance or increased production needs. As systems age, manufacturers are also faced with having to come up with spare parts that are no longer available. Manufacturers often turn to Paquette & Associates to improve the throughput of systems or rebuild where spare parts availability is an issue. We offer the ability to implement improvements at the customer’s facility or rebuild equipment at our site for later re-installation at client facilities.

Recent Machine/System Debug and Upgrade projects include:

Component Updating: SCARA Robot

Technology changes fast and many components (robotics, servos, motor drives, and PLC control systems) that were state of the art 10 years ago are no longer available. Many manufacturers turn to us to engineer upgrades and modifications to extend the lifespan of equipment where replacement parts are an issue.

We upgraded a SCARA robot and vision system that was originally installed 8 years ago. The client chose to replace these items in anticipation of the robot and vision system parts becoming unavailable due to discontinuation of the system by the manufacturer.

Mechanical Rebuild and Redesign: System Upgrade

Eliminating bottlenecks is on every manufacturing engineer’s “to-do” list, but with limited time, it is a day-to-day reality they are often unable to correct. Engineering Management routinely turns to Paquette & Associates to eliminate bottlenecks.

We recently completed an upgrade to a Fortune 100 company’s manufacturing line that reduces downtime by 1%, resulting in over $250,000 in yearly savings.

Power and Control System Rebuild and Redesign

Adding additional equipment to existing facilities and production lines can require power and controls system upgrades. Sometimes these updates are as simple as adding terminal blocks and relays, but often require more extensive upgrades. In addition, changes in electrical codes and insurance requirements force updates to power and controls systems. Paquette & Associates routinely manages these upgrades for clients.

We recently implemented electrical, PLC programming, and HMI program changes to support process changes implemented by the customer.

Controls System Programming

The controls operation of any system is as important as the mechanical operation. Quite often when mechanical changes are being implemented, controls changes are also required, and there are times when controls changes alone can improve system performance.

A local manufacturer had a system that was experiencing high down time due to an electrical controls problem. One of our controls engineers traveled to their facility and within hours had identified and resolved the problem.

Debug: System Debug

As system integrators and machinery builders, our experience with diagnosing and resolving equipment problems is extensive. Many manufacturers have the skill needed to resolve their equipment problems but not the time to implement the needed changes.

Recently a client had a new system manufactured by another company that was not working as required. We had experience with the technology being employed and were brought in to debug the system. Our resulting solution is unique and is being considered for a patent.